Calculating the Joint Stiffness Factor for a Bolted Connection

The information presented in this blog post is for educational purposes only. It should not be used for engineering design or relied upon as engineering advice.

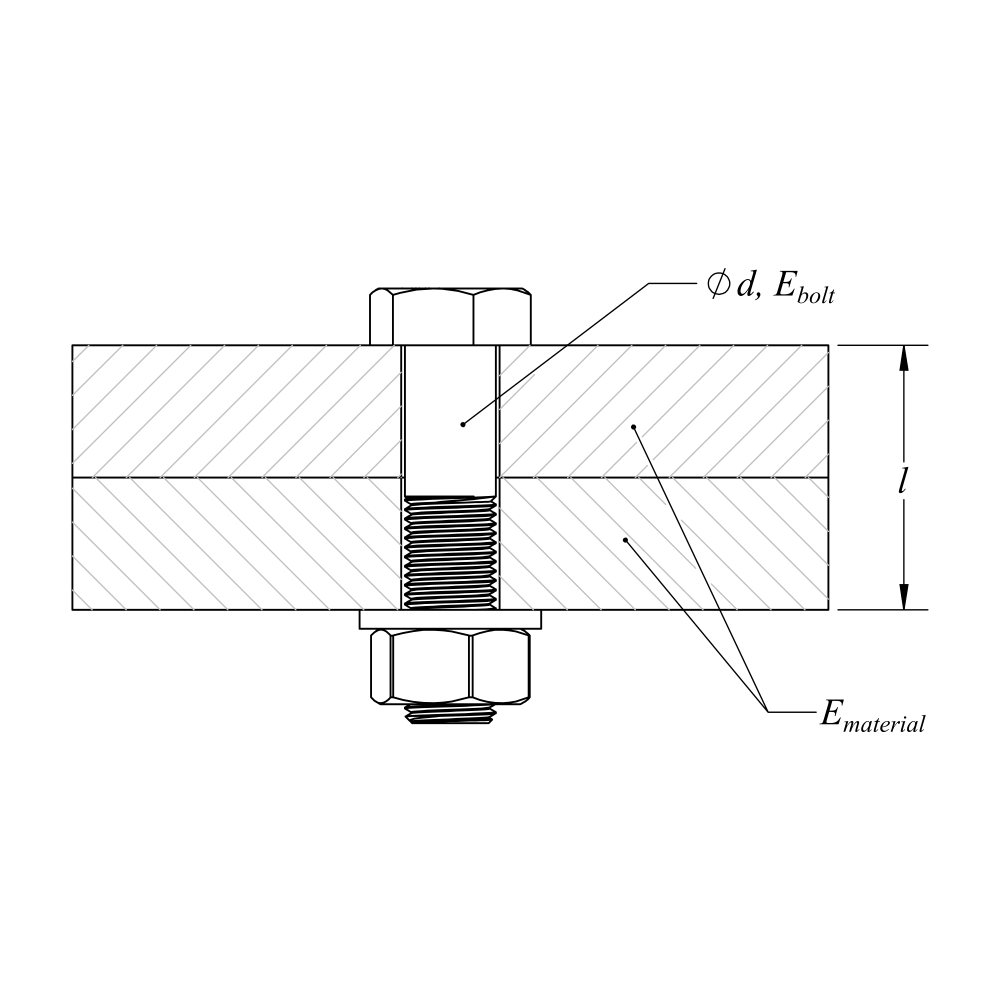

The analysis of a bolted connection requires determining the portion of the load that is carried by the fastener and the portion carried by the clamped material. The joint stiffness factor (also known as the joint stiffness constant, joint constant, or load factor) allows one to determine the total load on the fastener, $F_b$, using the following equation:

$$F_b =F_i +CP$$

where $F_i$ is the fastener preload, $C$ is the joint stiffness factor, and $P$ is an external tension load applied to the bolted connection. Since $C$ is less than 1, the portion of the external load seen by the fastener is less than the total load applied to the joint making the joint stiffness factor important in calculating the fatigue life of bolted connections. The joint stiffness factor is also needed to calculate the resulting clamping force holding the material together, $F_m$, using the following equation:

$$F_m = F_i -(1-C)P$$

Joint separation occurs when an external load is applied that is large enough to make the material clamping force less than or equal to zero.

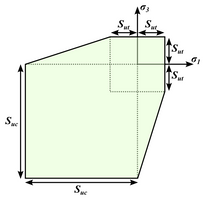

Determining the joint stiffness factor depends on the relative stiffness of the bolt and the clamped material. The details of what portions of the clamped material carry the load become important as well, since the larger this area, the smaller the joint stiffness factor. One approach is to approximate the load bearing portion of the clamped material as a cone or frustrum. This is the approach suggested by Shigley [1]. A second approach leverages finite element analysis (FEA) to simulate the joint stiffness factor for a variety of geometries and to fit an empirical relationship to this FEA data. This is the approach suggested by Norton [2], based on the work by Cornwell [3], and is the approached used by the joint stiffness factor calculator below. This approach has the advantage that it also accounts for the stiffness of the bolt head, which can have a significant impact on the resulting joint stiffness factor.

This joint stiffness factor calculator example sheet may also be opened in a separate tab.

[1] Budynas, Richard G., et al. Shigley’s Mechanical Engineering Design. With Kiatfa Tangchaichit, 11th edition, McGraw-Hill Education, 2020.

[2] Norton, Robert L. Machine Design: An Integrated Approach, 5th edition, Prentice-Hall, 2014.

[3] Cornwell, R E. “Computation of Load Factors in Bolted Connections.” Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, vol. 223, no. 4, Apr. 2009, pp. 795–808. DOI.org (Crossref), https://doi.org/10.1243/09544062JMES1108.